Having issues trying to get the backlit LED to be more visible through the white on white plastic advanced. Solidworks parts, icon indented from the inside, with black gasket surrounding the triangular shape used to apply the emissive material to. Brightness set to 800. Global illumination on. Photographic image with bloom set at 1.12, 61, .73

Sometimes for me it worked better when I used the Plastic Polycarbonate from the Plastic > Optical materials. You could try if that helps.

Try to use area light material instead of emissive.

This seems to make the entire panel tranparent.

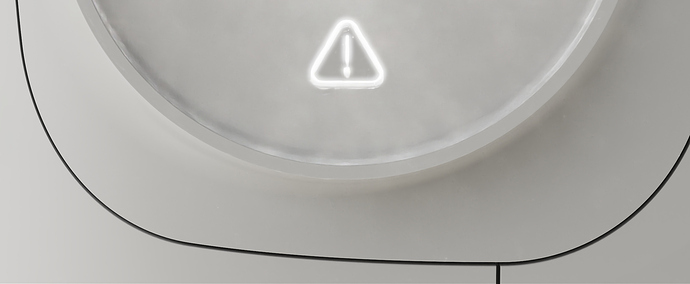

Area light seems to be doing something. It takes a bit longer to render of course. Likely what I will have to do is just go with the tried and true label addition with emissive. Just does not look as realistic.

also one thing that might work is to use the Dielectric material when you can for transparent stuff, it seems to render a LOT faster than others, and you can still bugger it up with bump maps, roughness, etc to make it look like others.

Going with the area light will work too, seems more true to life than the emissive lights. emissive work great when they don’t have to go through objects, but area lights and spot lights work better when interacting with transparent things.

One material that is my absolute fav (other than the Hammertone Paint material ) is that there is one called Clear Copolyester, not sure why exactly, maybe it just works really well with my lighting setups.

also, one thing my after effects guy taught me is that if you want something to appear bright (especially if its white) you have to make everything else darker. Within reason, this has had a huge effect on my renders of our lighting products.

When I use the white plastic and try to make it more realistic by making the material an area light the render times go through the roof. I have two RTX A5000’s and most times the renders at 1000 samples are super quick but this is making a definite impact. And not necessarily in a good way. Maybe I should just leave well enough alone and fake it with the emissive label solution. It is odd though that the area lights even at .125 watts are visible through the plastic. Here is the most recent run at 500 samples. Looks terrible. And thanks for the advice on the lighting environment. I have a darker environment with one side panel light but have found that helps when rendering white products.

Unfortunately lights also cause noise and with the denoiser on you get a smudgy result. I really hope that gets improved. I think I would also take the emissive label cheat if I had to make something like that.

I know, it’s sounds stupid - but you in ‘Product’ mode lighting, not ‘Interior’, right?

Yes product mode lighting is engaged.

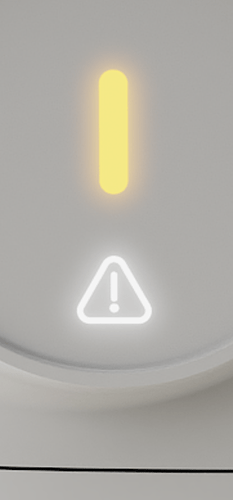

I really wish there was an easier solution. But alas you may be correct. Here is my rendition for the emissive label hackery.

I think it looks nice! Maybe if you need a real close-up shot you can’t use the emissive texture since you need some details. I think a lot of product shots you see have actually photoshopped/textured emissive things since it saves a lot of time. Although I also like to puzzle a bit and see if I can make things work using lights/geometry.

Believe me, I get the struggle and I stopped struggling and just use emissives when I can. I’ve also gone as far as to make an image texture in PS and map it to the part to make it look lit up,. A lot of our LED’s have a lot of "Depth’ to them, so that the LED’s are actually buried deep on the pcb boards and the use of light pipes to get the light to the user makes them look very not even and solid, as the image here- Changing the part to emissve and then I will use an opacity gradient in the material to sort of shape the fade of the LED output towards the edges goes a long way to match the actual product.

These are actual discs inside with an area light material on them. The tweaking of the plastic material that is the light pipe is super touchy and important in these cases, and Im’ not really sure what controls do what on here, I usually will mainly mess around until I find something that works, nothing as intelligent as intellectual testing going on here

This one has just a color gradient made in the mat graph in KS that provides the illusion of lit up led. There is zero photon emissions going on here. the glow/bloom was added in photoshop

and this one has actual little spotlights deep inside shining up through the cad modeled light pipes using the copolyester clear plastic material.

Appreciate the extensive description on the various options. I have in the past utilized similar approaches depending upon what I am looking to communicate. Maybe the key to all of this is flexability.